How to clean:

1, if there is dust on the ptfe gasket, wipe it with a cloth.

2, if it is oil, it is necessary to use organic solvents to clean, because oil is insoluble in water, soluble in organic solvents (such as alcohol, acetone, etc.), do not need to worry about tetrafluorine gaskets will be organic solvents corrosion, because the corrosion resistance of gaskets against organic solvents performance is very outstanding.

3, tetrafluorine gasket with organic solvent cleaning, as long as the toothbrush scrub clean, dry water on the good.

4, polytetrafluoroethylene -- commonly known as: plastic king. English name: Polytetrafluoro ethylene, commonly known as "non-stick coating" or "easy to clean material.

Specific gravity: 2.1-2.2 g/cm3

Molding shrinkage: 3.1-7.7%

Mold temperature: 330-380 ℃

Material performance:

1, long-term use temperature -200- 260 degrees, has excellent resistance to chemical corrosion, corrosion resistance to all chemicals, friction coefficient in the plastic in the lowest, and very good electrical performance, its electrical insulation is not affected by temperature, known as the "king of plastics".

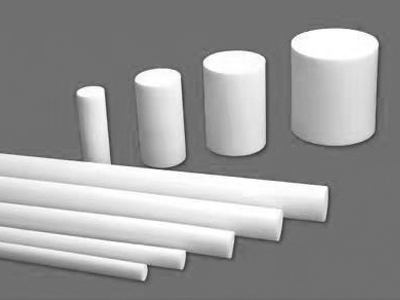

2, transparent or translucent state, the higher the crystallinity, the worse the transparency. The raw materials are mostly powder resins or concentrated dispersions with extremely high molecular weight and high crystallinity of thermoplastic polymers. Suitable for making corrosion resistant parts, wear resistant parts, seals, insulation parts and medical equipment parts

Molding performance:

1. Crystal material, small moisture absorption.

2. Poor fluidity, easy to decompose, and corrosion gas is generated during decomposition. The molding temperature should be strictly controlled, the mold should be heated and the casting system should have little resistance to the material flow.

3. Powder resin is usually formed by powder metallurgy and sintered. Sintering temperature 360-380 degrees, not more than 475 degrees. Emulsion resin is usually processed by cold extrusion and resintering process, which can form an anticorrosive layer on the surface of articles. If the product transparency and toughness are required, rapid cooling should be adopted. Also can take extrusion molding, can extrude tube, bar, profile.

4, PTFE melt viscosity is very high, the volume viscosity decreases with the increase of shear stress, showing its non-newtonian fluid characteristics.

5, secondary processing, can be hot-pressed composite, welding, bonding, strengthening, mechanical processing, etc., in order to produce the final product.